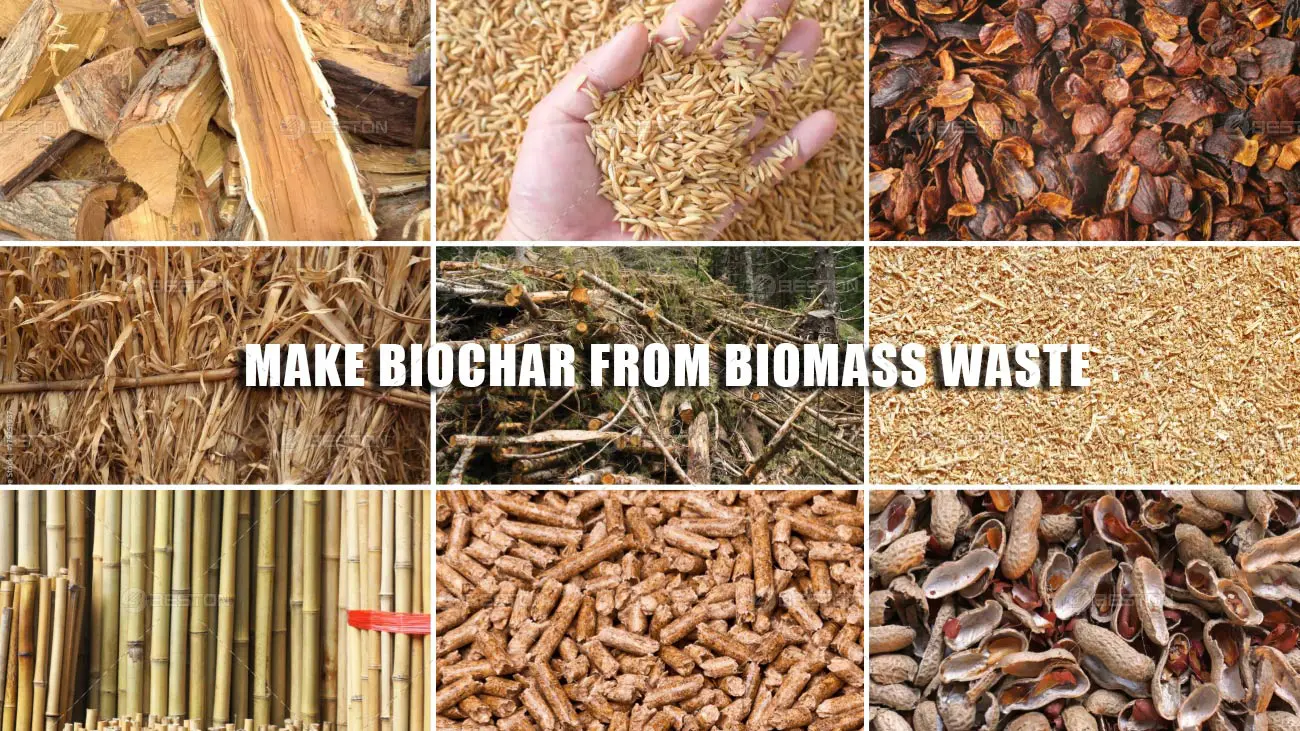

Complexities in Feedstock Characterization

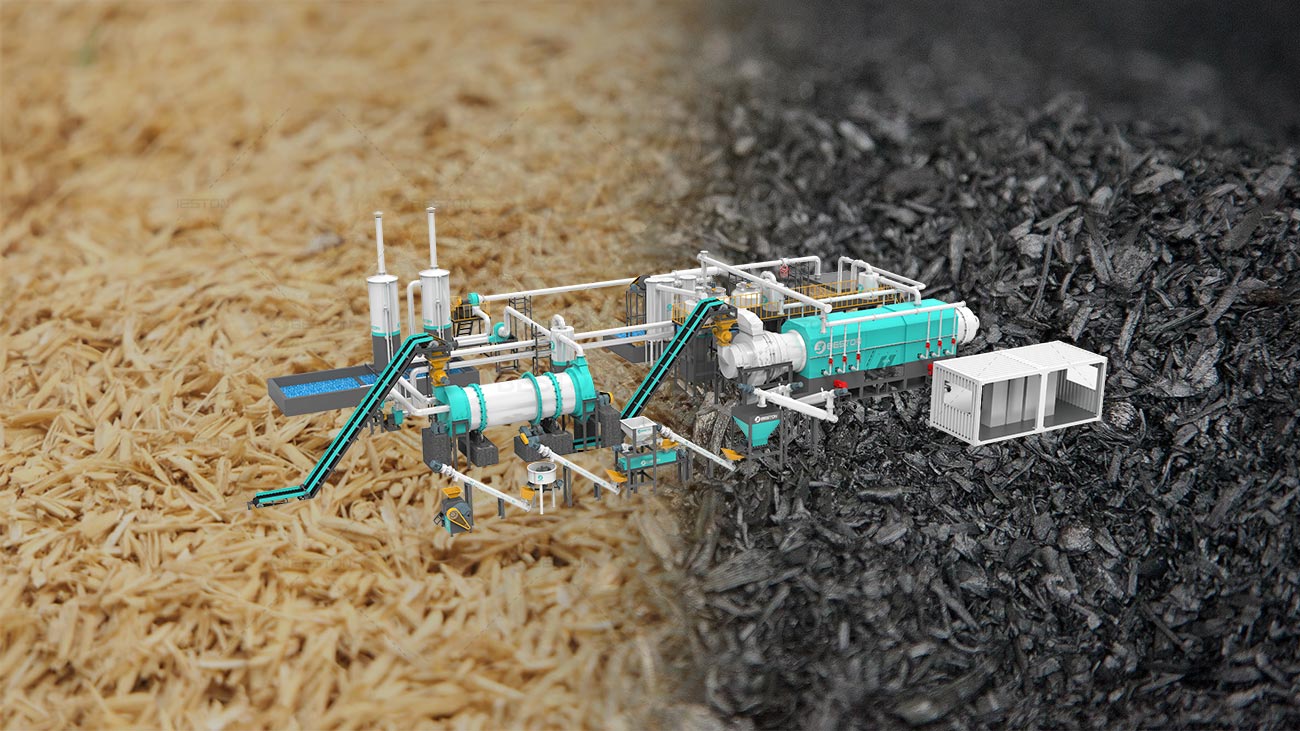

Biochar carbon removal systems rely heavily on consistent biomass feedstock quality. Variations in lignocellulosic composition, moisture levels, and trace mineral content can substantially influence carbonization efficacy. Short inconsistencies lead to long-term deviations. This challenge intensifies when sourcing agricultural residues from distributed suppliers, where moisture gradients and contamination are difficult to standardize. Precise feedstock preprocessing is mandatory, yet seldom straightforward. Advanced drying, homogenization, and contaminant-screening protocols add operational complexity and require robust monitoring architectures.

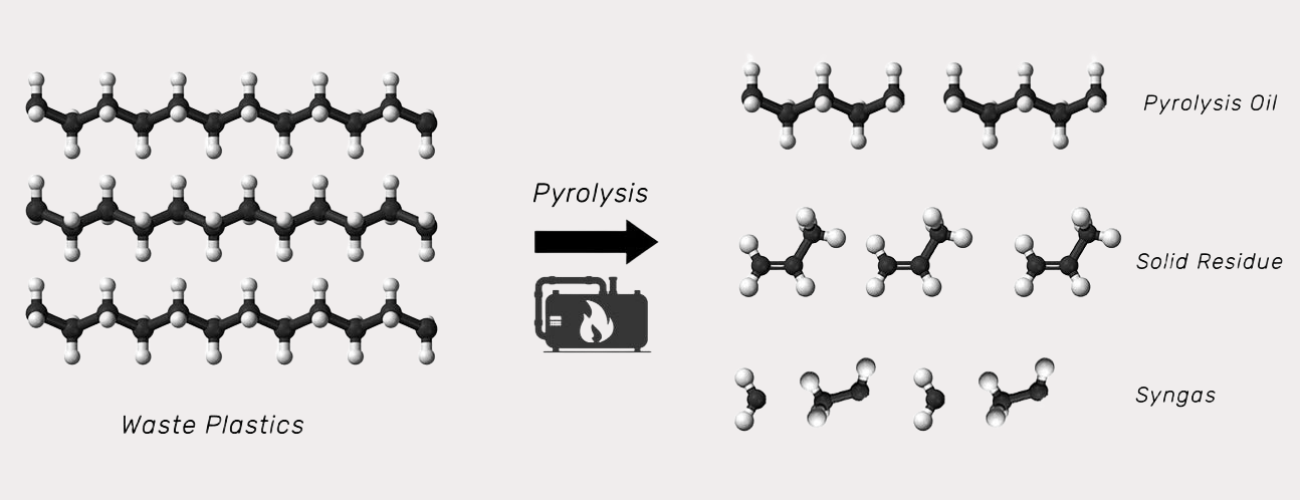

Thermochemical Process Constraints

The thermochemical reactions underlying biochar generation demand stringent control. Maintaining narrow thermal envelopes within a pyrolysis reactor ensures stable carbon sequestration properties. However, each biomass type responds uniquely to temperature, pressure, and residence time. These factors complicate scalability. Even minor fluctuations may compromise fixed-carbon content or introduce volatile impurities. In an industrial biochar machine, implementing continuous monitoring through infrared thermography, real-time gas analytics, and high-frequency feedback loops becomes essential. Achieving such precision often requires sophisticated automation not yet widely adopted across emerging carbon removal enterprises.

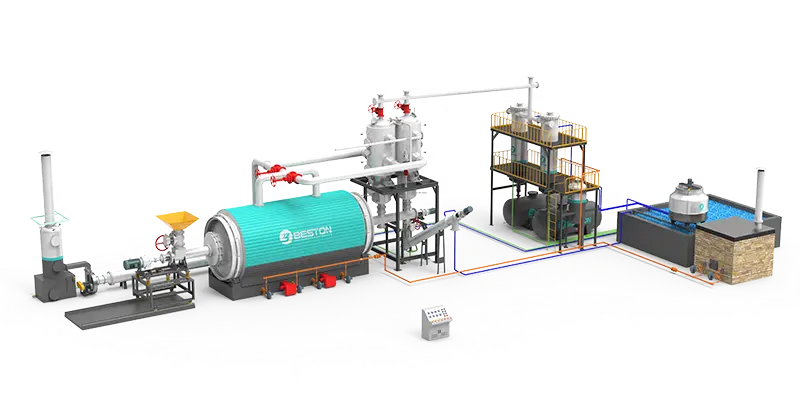

Challenges in Reactor Design and Durability

Reactor engineering plays a pivotal role in carbon retention performance. High-temperature exposure, abrasive particulates, and heterogeneous feedstock flows place extreme mechanical stress on internal linings. Refractory degradation is a recurrent issue. Over time, micro-cracking and thermal fatigue reduce efficiency and induce unplanned downtime. Designing biochar pyrolysis machine that sustain prolonged throughput without compromising thermal integrity demands advanced materials and costly fabrication methods. Modular design strategies mitigate risk, yet introduce complexity in system integration.

Verification and Measurement Hurdles

Biochar carbon removal requires rigorous quantification to validate climate benefits. Establishing reliable measurement, reporting, and verification (MRV) frameworks is one of the most difficult technical obstacles. Carbon stability varies with feedstock type, pyrolysis conditions, and post-processing practices. Determining long-term sequestration potential demands standardized analytical methods—such as proximate and ultimate analysis, recalcitrance evaluation, and isotopic tracing. Long sentences clarify complexity. Short sentences highlight risk. Without harmonized protocols, project developers face uncertainty when certifying carbon credits or engaging with external auditors.

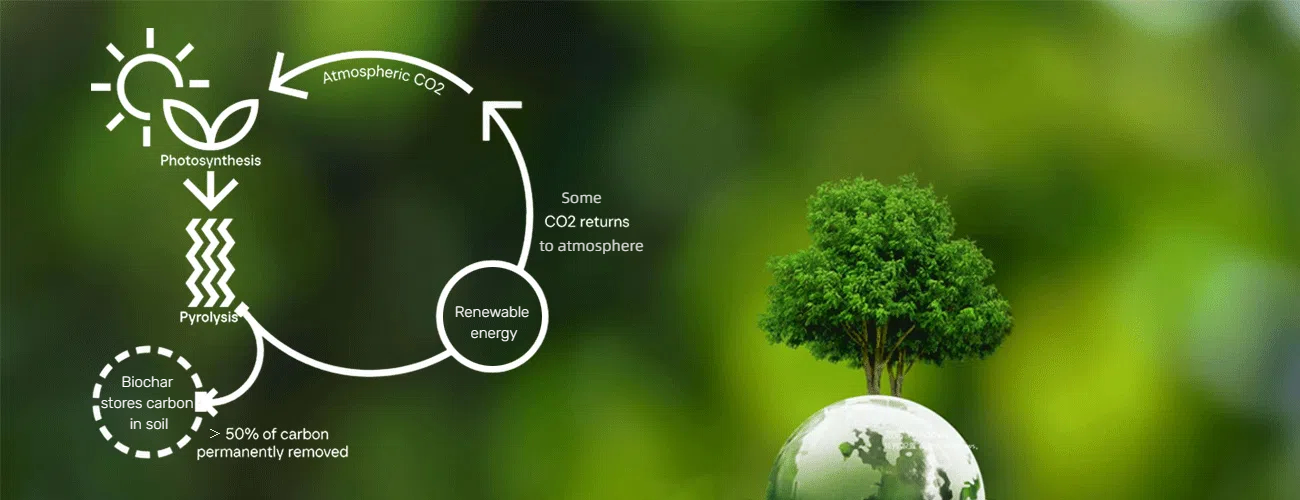

Soil Integration and Ecological Variability

Deploying biochar into soil systems introduces additional technical constraints. Soil heterogeneity, microbial dynamics, and climatic variations influence decomposition rates and carbon persistence. Some soils enhance stabilization; others accelerate mineralization. Predicting these interactions requires region-specific modeling, long-term field trials, and multidisciplinary expertise. The absence of universally accepted soil application guidelines complicates operational planning, especially for large-scale carbon removal projects catering to varied geographies. Implementation thus becomes a site-dependent engineering challenge rather than a uniform process.

Energy Balancing and System Efficiency

Maintaining energy neutrality or positivity remains essential for project credibility. A biomass pyrolysis plant may consume significant energy for feedstock preparation, thermal processing, and biochar handling. Insufficient heat recovery systems undermine overall carbon efficiency. Deploying recuperative exchangers, syngas utilization modules, and optimized insulation reduces parasitic loads, yet requires refined engineering. The interdependence of these subsystems creates intricate design dependencies. Misalignment in any component risks offsetting the intended climate benefits, posing a formidable barrier for new operators.

Scaling Constraints and Supply Chain Fragility

Scaling biochar projects from pilot to commercial stages exposes material and logistical bottlenecks. Procuring consistent biomass volumes while maintaining cost efficiency is challenging. Transporting low-density biomass over long distances inflates operational costs. Establishing localized supply networks mitigates this issue but requires coordinated partnerships with agricultural producers, forestry operations, or municipal waste managers. Infrastructure disparities further complicate deployment. Fragmented supply chains can impede throughput continuity and delay carbon credit generation. Obtain biochar carbon removal solutions: https://bestonmachinery.com/

Regulatory Misalignment and Standardization Gaps

Regulatory frameworks for biochar carbon removal remain in flux. Certification bodies, environmental agencies, and carbon marketplaces employ heterogeneous criteria. Developers are often required to retrofit processes or reconfigure sampling protocols to meet shifting compliance standards. Standardization gaps in MRV, biochar quality grading, and land application regulations create persistent uncertainty. This lack of regulatory cohesion acts as a substantial technical barrier, as projects must anticipate future compliance trends without clear guidance.